Intrinsically safe explosion-proof for pressure sensor Zener-barrier

Zener-barrier series VEK216

- Explosion-proof rate

Zener-barrier: ⅡC / Pressure sensor: ⅡC T4 Ga

| Applicable Sensor | VPRF(IS), VPRQ(IS), VPRQF(IS), VPRNP(IS) |

|---|---|

| Measured medium | VPRF(IS), VPRQ(IS), VPRQF(IS): SUS630 and 15-5PH (precipitation-hardened stainless steel) VPRNP(IS): Media that will not corrode SUS316L (Refer to the individual specifications.) |

| Measured Range | VPRNP(IS): 100 to 1700kPa or 100 to 1700kPa abs VPRQ(IS), VPRF(IS): 1 to 50MPa VPRQF(IS): 1 to 100MPa (Refer to the individual specifications.) |

[Zener-barrier] Specifications

| TIIS Certification Number | No. TC22249 |

|---|---|

| Model | VEK216 |

| Explosion-proof structure | Intrinsic safety explosion-proof structure (To be installed in non-hazardous area) |

| Explosion-proof performance | [Ex ia] ⅡC |

| Grounding | Independent class A grounding required. |

| Rating | Max. voltage of intrinsically safe circuit: 14.4V Max. current of intrinsically safe circuit: 150mA Max. power of intrinsically safe circuit: 270mW Max. inductance allowed in the intrinsically safe circuit: 0.79mH Max. capacitance allowed in the intrinsically safe circuit: 335nF Max. voltage allowed in the non-intrinsically safe circuit: 250V AC 50/60Hz, 250V DC Ambient Temperature: -20 to ;+60°C |

[Pressure sensor] Specifications

| TIIS Certification Number | No. TC22316X | No. TC22317X | ||

|---|---|---|---|---|

| Applicable sensor series | VPRNP(IS) | VPRF(IS) | VPRQ(IS) | VPRQF(IS) | Explosion-proof structure | Intrinsically safe explosion-proof structure |

| Explosion-proof performance | Ex ia ⅡC T4 Ga | |||

| Input voltage | ±2.5V or 5V | |||

| Rating | Max. voltage allowed in the intrinsically safe circuit: 14.4V Max. current allowed in the intrinsically safe circuit: 150mA Max. power allowed in the intrinsically safe circuit: 0.270W Inside inductance: 0.28mH Inside capacitance: 32nF Ambient Temperature: VPRF(IS), VPRQ(IS), VPRQF(IS): -20 to +60°C, VPRNP(IS): -20 to +50°C |

|||

| Measured medium | VPRF(IS), VPRQ(IS), VPRQF(IS): SUS630 and 15-5PH (precipitation-hardened stainless steel), VPRNP(IS): Media that will not corrode SUS316L |

|||

| [terms of use] |

|---|

| Risk of ignition by shock or friction Aluminum alloy is included in the structural material of the enclosure. Since the mass fraction of the aluminum alloy is more than the predetermined value, there is a potential risk of ignition. Do not drop the product or subject it to excessive shock or friction. Risk of electrostatic charge Non-metallic materials are included in the surface of the enclosure. To avoid the risk of ignition, take measures to prevent electrostatic charge. |

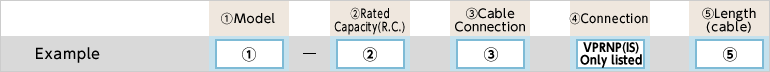

Model Selection

| Photo | ①Model | ②Rated Capacity(R.C.) | ③Cable Connection | ④Connection Screw | ⑤Length(Cable) | |

|---|---|---|---|---|---|---|

|

VPRF(IS) | 1MP(1MPa) 2MP(2MPa) 5MP(5MPa) 10MP(10MPa) 20MP(20MPa) 50MP(50MPa) |

Blank (Standard connector) W (Waterproof connector) |

G3/8 | 3m(Standard) 5m 10m □□m If you prefer other length(*3) |

|

|

VPRQ(IS) | 1MP(1MPa) 2MP(2MPa) 5MP(5MPa) 10MP(10MPa) 20MP(20MPa) 35MP(35MPa) 50MP(50MPa) |

R3/8 | |||

| VPRQF(IS) | 1MP(1MPa) 2MP(2MPa) 5MP(5MPa) 10MP(10MPa) 20MP(20MPa) 35MP(35MPa) 50MP(50MPa) 100MP(100MPa) |

G3/8 (100MPa: G1/2) |

||||

|

VPRNP(IS) | Guage Pressure | 100(100kPa) 200(200kPa) 700(700kPa) 1700(1700kPa) |

R3/8 G3/8 Specify thread size. |

||

| Absolute Pressure | 100A(100kPa abs) 200A(200kPa abs) 700A(700kPa abs) 1700A(1700kPa abs) |

|||||

- Note

- *1 Always use in combination with VALCOM amplifier.

Models are subject to change in part due intrinsic safety or explosion-proof purpose. Always contact our sales office for confirmation. - *2 Please order the cable length between VALCOM amplifier and Zener-barrier.

- *3 Between Conformity sensor and Zener-barrier use dedicated to cable for safe explosion-proof. (Max 200m / VPRNP guage pressure · W (Waterproof connector): Max 100m)

Examples of explosion-proof construction

(1) Pressure sensor

(2) Zener-barrier

| ①EPL | |

|---|---|

| Ga | Equipment having a very high level of protection that can be used in particularly hazardous locations. |

| Gb | Equipment having a high level of protection that can be used in Group I explosive gas atmospheres. |

| Gc | Equipment having an enhanced level of protection that can be used in Group II explosive gas atmospheres. |

| ② Temperature class | |

|---|---|

| T1 | Maximum surface temperature: Over 300°C and 450°C or less |

| T2 | Maximum surface temperature: Over 200°C and 300°C or less |

| T3 | Maximum surface temperature: Over 135°C and 200°C or less |

| T4 | Maximum surface temperature: Over 100°C and 135°C or less |

| T5 | Maximum surface temperature: Over 85°C and 100°C or less |

| T6 | Maximum surface temperature: 85°C or less |

| ③ Electrical equipment group | |

|---|---|

| ⅡA | Representative gas: Propane |

| ⅡB | Representative gas: Ethylene |

| ⅡC | Representative gas: Hydrogen |

| Only Group Ⅱ (Intended for use in locations where explosive gas atmospheres exist other than in a mine susceptible to firedamp) subdivisions are listed. Electrical equipment in Group Ⅱ are subdivided according to the nature of the explosive gas atmospheres in which the equipment is to be used, as shown in the table below (*4). |

|

| ④ Explosion-proof construction | |

|---|---|

| ia | Meets the requirements of intrinsically safe explosion-proof construction. |

| d | Meets the requirements of flameproof enclosure. |

Typical Explosive Gas Groups and Temperature Classes (*4)

| Temperature class | |||||||

|---|---|---|---|---|---|---|---|

| T1 | T2 | T3 | T4 | T5 | T6 | ||

| Group | ⅡA | Acetonitrile Acetone Ammonia Ethane Isopropyl chloride M-xylene P-xylene Acetic acid Ethyl acetate Ethyl bromide Styrene 1,2,4-Trimethylbenzene Toluene Propylene Benzene Methane |

Acetylacetone Isopentane Vinyl chloride O-xylene Isopentyl acetate Vinyl acetate Butyl acetate Propyl acetate Pentyl acetate Methyl acetate Diisopropyl ether Cyclohexanone 1.2-Dichloroethane Chiofeng 1-Butanol Butane Propane 2-Propanol 1-Pentanol Acetic anhydride Methyl methacrylate Methanol |

Butyl chloride Octane Cyclohexane Deccan Butyraldehyde Hexane Heptane Pentane |

Acetaldehyde | Ethyl nitrite | |

| ⅡB | Methyl acrylate Acrylonitrile Carbon monoxide Hydrogen cyanide |

Ethyl acrylate Ethanol Ethyl methyl ketone Ethylene Ethylene oxide Epichlorohydrin 1,4-Dioxane 1,3-Butagen Franc Propylene oxide |

Dimethyl ether Tetrahydrofuran 1-Hexanol |

(di)ethyl ether Dibutyl ether |

|||

| ⅡC | Water gas, Hydrogen |

Acetylene | Carbon bisulfide | ||||

[Note]

This table summarizes the classification of flammable gases and vapors according to the explosion-proof construction of electrical equipment.

It is intended as a basic reference for electrical technicians to be used for classifying hazardous locations and for selecting electrical equipment having adequate explosion-proof performance.

Ignition point, explosion limit, and flash point are discussed in many literatures. Consult them by yourself to select appropriate explosion-proof equipment.

(Reference) TECHNICAL RECOMMENDATION OF NATIONAL INSTITUTE OF OCCUPATIONAL SAFETY AND HEALTH "USER'S GUIDELINE for Installations for Explosive Atmospheres in General Industry" JNIOSH-TR-NO.44 (2012)

External dimensions (Unit: mm)

Wiring diagram